SCEC TPV13

TPV13 is similar to TPV12 except for the non-associative Drucker-Prager visco-plastic rheology.

The Drucker-Prager yield function is given by:

\(F(\sigma)=\sqrt{J_2(\sigma)}-Y(\sigma)\)

\(Y(\sigma)\) is the Drucker-Prager yield stress, given as:

\(Y(\sigma) =\max(0,c\cos \phi - (\sigma_m +P_f)\sin \phi)\)

with \(\sigma_m = (\sigma_{11}+\sigma_{22}+\sigma_{33})/3\) the mean stress,

\(c\) the bulk cohesion, \(\phi\) the bulk friction and \(P_f\) the fluid pressure (1000 kg/m \(^3\)). In TPV13 benchmark, \(c=\) 5.0e+06 Pa and \(\phi\) =0.85.

\(J_2\) is the second invariant of the stress deviator:

\(J_2(\sigma) = 1/2 \sum_{ij} s_{ij} s_{ji}\)

with \(s_{ij} = \sigma_{ij} - \sigma_m \delta_{ij}\) the deviator stress components.

The yield equation has to be satisfied:

\(F(\sigma)\leq 0\)

When \(F(\sigma) < 0\), the material behaves like a linear isotropic elastic material, with Lame parameters \(\lambda\) and \(\mu\).

Wen \(F(\sigma) = 0\), if the material is subjected to a strain that tends to cause an increase in \(F(\sigma)\), then the material yields and plastic strains accumulates.

Nucleation

TPV13 uses the same nucleation strategy as TPV12.

Plasticity parameters

To turn on plasticity in SeisSol, add the following lines in parameters.par:

&Equations

Plasticity = 1 ! default = 0

Tv = 0.03 ! Plastic relaxation

/

Plasticity related parameters are defined in material.yaml:

!Switch

[rho, mu, lambda, plastCo, bulkFriction]: !ConstantMap

map:

rho: 2700

mu: 2.9403e+010

lambda: 2.941e+010

plastCo: 5.0e+06

bulkFriction: 0.85

[s_xx, s_yy, s_zz, s_xy, s_yz, s_xz]: !Include tpv12_13_initial_stress.yaml

Results

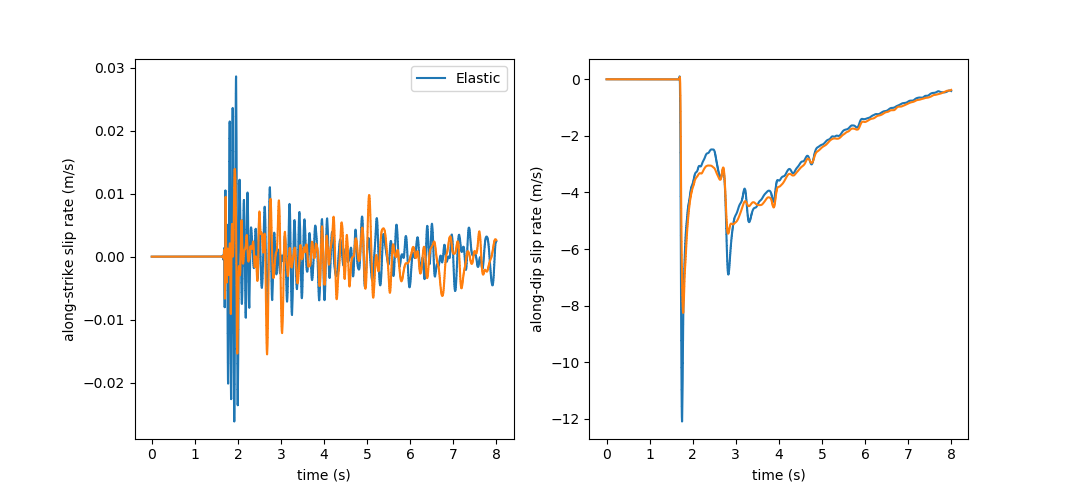

Figure 1 compares the slip-rates along strike and dip in TPV12 (elastic) and TPV13 (visco-plastic). The peak slip rate in TPV12 is higher than in TPV13. This difference can be attributed to the inelastic response of the off-fault material. See Wollherr et al. (2018) for detailed discussions.

Figure 1: along-strike (left) and along-dip (right) slip rate in TPV12 (blue) and 13 (orange).